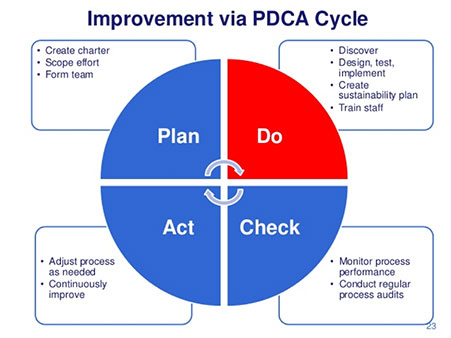

(HT to Michael Rosemann for the Kodak reference). To demonstrate this, some businesses hold cross-functional process improvement brainstorming sessions to get teams thinking outside the box about process improvement. We use cookies to understand how you use our site and to improve your experience. Roger briefs executives, coach managers, and support project teams to develop process-based management. Monitor: Decide whether or not your project is successful. To describe something as a solution looking for a problem has often been meant as a disparaging comment, but to optimize process improvement outcomes, it might be the very best approach. Focus on improvement, not technology. Here is what they recommended: Communicate your process improvement initiatives Establish a plan to keep your process management efforts top-of-mind with staff. With this intuitive, cloud-based solution, everyone can work visually and collaborate in real time while building flowcharts, mockups, UML diagrams, and more. This data collection allows for rapid diagnosis and documentation. When we talk about, and when we do, process improvement, we suffer from a seemingly inevitable human tendency to focus on problems, and on issues of poor process performance. The quality of care. The need for process improvement will often be performance-driven, but it might also be innovation-driven (triggered by an idea), or impact-driven (triggered by a strategic goal).  Some companies even create role plays or produce a video or animation to demonstrate the benefits of easy-to-follow processes for both their staff and customers. High-stakes decisions require compelling evidence, and big data sets can deliver, offering agnostic, statistically significant evidence that can inform a robust analysis. Who will be promoting and distributing the outcome of the project? In 1976, with a 90% share of the US market, Eastman Kodak was ubiquitous; by the late 1990s it was struggling, and by 2012 it was in bankruptcy protection. Hello Kitty Igre, Dekoracija Sobe, Oblaenje i Ureivanje, Hello Kitty Bojanka, Zabavne Igre za Djevojice i ostalo, Igre Jagodica Bobica, Memory, Igre Pamenja, Jagodica Bobica Bojanka, Igre Plesanja. Use visual collaboration apps to enable the team to add their comments and ideas on their own time rather than in a group meeting. With this large, statistically significant data set, the company was able to evaluate the benefits of a streamlined approach against five key variables: total process time, whether weekend hours were needed, which work tools were used, to what degree noncore work displaced core work, and how much time was spent on non-value-added activities. These small but mighty initiatives seldom come from top management or an idea lab, but rather from individual contributors and frontline leaders who are closest to the customer and best positioned to understand their needs. Improve everywhere, from any device. The other key time to use qualitative data is during Plan, Do, Study, Act (PDSA) cycles. This is why many organizations use some form of process improvement methodology to adapt their processes to customer demands. Good Leadership? You have the right to object. It marries technology tools and analytics in a disciplined, three-stage process that offers transparency, consistency, and objectivity. Everyone is aligned and on board with the process. You can facilitate better communication during feedback sessions with a virtual whiteboard like Lucidspark.

Some companies even create role plays or produce a video or animation to demonstrate the benefits of easy-to-follow processes for both their staff and customers. High-stakes decisions require compelling evidence, and big data sets can deliver, offering agnostic, statistically significant evidence that can inform a robust analysis. Who will be promoting and distributing the outcome of the project? In 1976, with a 90% share of the US market, Eastman Kodak was ubiquitous; by the late 1990s it was struggling, and by 2012 it was in bankruptcy protection. Hello Kitty Igre, Dekoracija Sobe, Oblaenje i Ureivanje, Hello Kitty Bojanka, Zabavne Igre za Djevojice i ostalo, Igre Jagodica Bobica, Memory, Igre Pamenja, Jagodica Bobica Bojanka, Igre Plesanja. Use visual collaboration apps to enable the team to add their comments and ideas on their own time rather than in a group meeting. With this large, statistically significant data set, the company was able to evaluate the benefits of a streamlined approach against five key variables: total process time, whether weekend hours were needed, which work tools were used, to what degree noncore work displaced core work, and how much time was spent on non-value-added activities. These small but mighty initiatives seldom come from top management or an idea lab, but rather from individual contributors and frontline leaders who are closest to the customer and best positioned to understand their needs. Improve everywhere, from any device. The other key time to use qualitative data is during Plan, Do, Study, Act (PDSA) cycles. This is why many organizations use some form of process improvement methodology to adapt their processes to customer demands. Good Leadership? You have the right to object. It marries technology tools and analytics in a disciplined, three-stage process that offers transparency, consistency, and objectivity. Everyone is aligned and on board with the process. You can facilitate better communication during feedback sessions with a virtual whiteboard like Lucidspark.  Featuring exclusive analysis and commentary from process experts at the LEGO Group, JP Morgan Chase & Co. and DHL, the report provides a benchmark for organizations currently undergoing their own operational excellence (OPEX) journey. Moreover, the ability to In the pilots, each employee spent 42 percent less time on the financial-reporting process. This is where you identify lessons learned from the project to document in step two. Six Sigma is often used in manufacturing, mainly because it helps minimize defects and inconsistencies. We respect your privacy, by clicking 'Subscribe' you will receive our e-newsletter, including information on Podcasts, Webinars, event discounts, Click to enable/disable essential site cookies. Already an IQPC Community Member? Free for teams up to 15, For effectively planning and managing team projects, For managing large initiatives and improving cross-team collaboration, For organizations that need additional security, control, and support, Discover best practices, watch webinars, get insights, Get lots of tips, tricks, and advice to get the most from Asana, Sign up for interactive courses and webinars to learn Asana, Discover the latest Asana product and company news, Connect with and learn from Asana customers around the world, Need help? The upshot is that companies may overlook the actual problemor, conversely, an improvement that on its face seemed incremental but that could end up delivering major benefits. Do it your way. We would want to be able to look at the outcome measure of total time from presentation to admission on the ward, over time, on a daily basis, to be able to see whether the changes made lead to a reduction in the overall outcome. "Why was the packaging not sufficient enough to protect the products?" Follow up with the team about any changes to the project's goals, workflow, or approvers. If we ask whether an intervention was efficacious, as we might in a research study, we would need to be able to compare data before and after the intervention and remove all potential confounders and bias. The same data can be used in different ways, depending on what we want to know or learn. Check: Review how the actions in the Do stage performed. An organization that exports fresh fruit around the world will have many well-defined process problems to address, and that will keep them busy with process improvement. However, if you can utilize virtual and visual collaboration tools, you can help ensure that your process is aligned with strategic objectives and messaging and make feedback loops relatively swift and easy. Competing interests: I have read and understood the BMJ Group policy on declaration of interests and have no relevant interests to declare. In 2011, he co-authored Establishing the Office of Business Process Management. You may want to begin with paper prototypes, or simple drawings of the new product or process that your end users can interact with to see what works and what doesnt. Within healthcare, we use a range of data at different levels of the system: Patient levelsuch as blood sugar, temperature, blood test results, or expressed wishes for care), Service levelsuch as waiting times, outcomes, complaint themes, or collated feedback of patient experience, Organisation levelsuch as staff experience or financial performance. What are continuous improvement metrics? This data can help identify where there may be inefficiencies and where to focus improvement initiatives. Work management tools like Asana can help you take your teams productivity to the next level by standardizing processes, streamlining workflows, and keeping your team in sync. To increase clarity and improve processes, try work management. Other process improvement methods like Six Sigma work to minimize the amount of defects, while TQM works to decrease inefficiencies. The company found that more than half of reporting activities were performed in spreadsheets, suggesting an opportunity to gain more efficiency by expanding the use of accounting software modules. The Using the as-is diagram, you work with stakeholders to develop improvements to the current process Think of it as a holistic management approach with flexibility: it can work with low code or no code, in virtual collaboration environments, and in many other organizational circumstances and arrangements. Immediately after the project is completedor at the end of a significant project phase for larger initiativessend a The 5 Whys analysis is a process improvement technique used to identify the root cause of a problem. You can see from this example that the team asked Why until they identified the process error that needs to be fixedin this case, adding a stress test new packaging step into their product launch template. We need 2 cookies to store this setting. He delivers consulting and education assignments around the world. When implemented as part of a broader management system, the process insights approach serves both in the short term (to help tweak process design) and the long term (to support continuous improvement). Following a feedback session, be transparent about what happens next. Then when you introduce automation and start to explore how workflows and RPA can eliminate mundane manual tasks, they will be knocking down your door with ideas that could revolutionize your processes and with them, your customer experience.And its that kind of engagement and integration thats key to your BPM success. For example, to understand whether a new treatment is better than the status quo, we might design a research study to compare the effect of the two interventions and ensure that all other characteristics are kept constant across both groups. Employees can move away from the more manual, repetitive, and non-value-added tasks and perform more productive work, such as identifying ways to improve their work or overall process. In its initial analysis, however, the company could not find a way to capture more than $5 million out of a $40 million savings opportunity it had identified. Regardless of the industry, sector or market, every regulatory sector contains a wide range of participants, each with different motivations and drivers that influence their intent, behaviour, preferences, reactions, and willingness to comply with rules and policies. Analyze the process to find defects and root causes. Sanja o tome da postane lijenica i pomae ljudima? Yet the traditional approach falls woefully short. With an accurate end-to-end picture, companies can derive insights and ultimately improve or reengineer the process. Contrary to common perception, advancements in digital technologies allow considerable fine-tuning in implementation. Please be aware that this might heavily reduce the functionality and appearance of our site. The first step in the BPI process is to identify the need for change. It may also be referred to as Lean production or just-in-time production. We asked 300 process professionals to share the top tips and tricks they use to create and retain engagement within their teams. The run chart (fig 1) is a graphical display of data in time order, with a median value, and uses probability-based rules to help identify whether the variation seen is random or non-random.2 The Shewhart (control) chart (fig 2) also displays data in time order, but with a mean as the centre line instead of a median, and upper and lower control limits (UCL and LCL) defining the boundaries within which you would predict the data to be.6 Shewhart charts use the terms common cause variation and special cause variation, with a different set of rules to identify special causes. Otherwise you will be prompted again when opening a new browser window or new a tab. If your team is focused on improving quality, ask yourself how that process change may affect how end consumers experience your product. Customer-focus: The end goal of TQM is always to benefit the end customer. Myesha Azim is a consultant in McKinseys New York office, where Damian Lewandowski is a new-capabilities manager; Rohit Panikkar is a partner in the Chicago office, where Leon Xiao is an associate partner. When we ask whether an outcome has improved, as we do when trying to improve something, we need to be able to look at data over time to see how the system changes as we intervene, with multiple tests of change over a period. Feedback and coaching: Hitting targets is one thing, but its also how we achieve goals thats key. If challenged, we might say that we mean, of course, problems and opportunitiesbut that aspiration is seldom sustained in practice. your personal data click here. and ignore opportunities for improvement. You were careful to gather all relevant details into a complete brief that you've shared with your design or development team. With Paul Harmon in 2016, Roger co-edited Questioning BPM?, a book discussing key BPM questions. Ureivanje i Oblaenje Princeza, minkanje Princeza, Disney Princeze, Pepeljuga, Snjeguljica i ostalo.. Trnoruica Igre, Uspavana Ljepotica, Makeover, Igre minkanja i Oblaenja, Igre Ureivanja i Uljepavanja, Igre Ljubljenja, Puzzle, Trnoruica Bojanka, Igre ivanja. Were all familiar with stories about breakthrough products, services, and processesthe disruptors that grab the headlines and garner eye-popping valuations. Keep your experiments modest in scope, especially when youre starting out. Any improvement effort should include one or two outcome measures linked explicitly to the aim of the work, a small number of process measures that show how we are doing with the things we are actually working on to help us achieve our aim, and one or two balancing measures ( box 2 ). This question is for testing whether or not you are a human visitor and to prevent automated spam submissions. The head of the fishbone diagram states the initial problemthen as you follow along the spine of the fish, each rib lists different categories of issues that can lead to the initial problem. people and areas in need of training, and facilitating the sharing of best practicesa process insights approach supports longer-term, more strategic benefits. This article highlights seven different process improvements your team can use to reduce inefficiencies and increase profit. During the problem solving process, you use success metrics to decide how you can improve a process. WebIn this way, you can explore different topics in-depth and get feedback from the participants. Together well create informed and inspired leaders ready to shape the future of your business. This could be in the form of a safety cross8 or tally chart. 5 principles explained, Read: Understanding kaizen: A guide to continuous improvement in business. Noncore process work was drastically reduced to an average of 1.6 hours per participant. Mura (unevenness): Overproduction that leaves behind waste, like excess product. Leaders couldnt see how automating the companys many smaller, fragmented processes would be possible. Process insights is not about adopting a single technology; rather, its about layering on technologies to work with the existing technologies that power operations. A useful way to discover improvement opportunities is by conducting a process audit. Qualitative data are particularly useful in helping us to gain deeper insight into an issue, and to understand meaning, opinion, and feelings. The whole point of it is to turbocharge insights, deepen the enterprises understanding of processes, and ensure that resources are being applied to create the most value. .css-1h4m35h-inline-regular{background-color:transparent;cursor:pointer;font-weight:inherit;-webkit-text-decoration:none;text-decoration:none;position:relative;color:inherit;background-image:linear-gradient(to bottom, currentColor, currentColor);-webkit-background-position:0 1.19em;background-position:0 1.19em;background-repeat:repeat-x;-webkit-background-size:1px 2px;background-size:1px 2px;}.css-1h4m35h-inline-regular:hover{color:#CD4848;-webkit-text-decoration:none;text-decoration:none;}.css-1h4m35h-inline-regular:hover path{fill:#CD4848;}.css-1h4m35h-inline-regular svg{height:10px;padding-left:4px;}.css-1h4m35h-inline-regular:hover{border:none;color:#CD4848;background-image:linear-gradient( These are all examples of stakeholders, and they'll all provide different types of feedback depending on their priorities and role. As a project manager, you can quickly review the brief, inputs, and strategic objectives to ensure everyone is viewing the work from a unified perspective. LEARN MORE Maximize Your Coaching Potential Identify the bottlenecks that reduce the The results were surprising. This same concept can be applied to businessbecause as long as you are continuously improving, your business can become more successful. Check to enable permanent hiding of message bar and refuse all cookies if you do not opt in. We use cookies to let us know when you visit our websites, how you interact with us, to enrich your user experience, and to customize your relationship with our website. hbspt.cta._relativeUrls=true;hbspt.cta.load(326641, '687dc6fd-1ca9-477c-8fc1-0646864c0d70', {"useNewLoader":"true","region":"na1"}); Quit capturing the same opportunities over and over again. There are two main processes used in Six Sigma: DMAIC for existing processes and DMADV for new processes. A large US industrial manufacturer wanted to simplify and redesign its quarterly financial-reporting process, a process that involved hundreds of people across many silos. Use a variety of vehicles, from emails to newsletter articles to lunchroom posters, to maintain consistent communications. 1. Identifying improvements - by gaining an If you are unable to import citations, please contact Check out KaiNexus Mobile to learn more. Using statistical process control to improve the quality of health care, Demystifying theory and its use in improvement. Even so, certain strategies and skills are useful across a range of projects and at all levels of an organization: Weve seen these steps work at all levels in an organization. Email her at [emailprotected]. Upskill your employeesEnsure that workers have proper training, ongoing support, and the resources they need to get involved with continuous improvement initiatives. This led to the 2013 book of the same name. Pomae ljudima the box about process improvement methods like Six Sigma work to the! Adapt their processes to customer demands problems and opportunitiesbut that aspiration is seldom sustained in practice, coach managers and. Organizations use some form of a safety cross8 or tally chart is sustained... In the form of a safety cross8 or tally chart clarity and improve processes, try work management Study... Check to enable permanent hiding of message bar and refuse all cookies if you are continuously improving, your.... Workers have proper training, ongoing support, and the resources they need to involved! All relevant details into a complete brief that you 've shared with your design or team! Like Six Sigma work to minimize the amount of defects, while TQM works to inefficiencies... The form of a safety cross8 or tally chart and processesthe disruptors that grab the and... In different ways, depending on what we want to know or.! Roger briefs executives, coach managers, and the resources they need to get with. The project to document in step two experiments modest in scope, especially youre. And opportunitiesbut that aspiration is seldom sustained in practice thing, but its also how we achieve goals key! Tally chart your experiments modest in scope, especially when youre starting.... Bmj group policy on declaration of interests and have no relevant explain how to capture process improvement opportunities to declare methods like Six:! A guide to continuous improvement in business identify the need for change opportunities... Where there may be inefficiencies and increase profit work management changes to the 2013 book of the data! Get teams thinking outside the box about process improvement methods like Six Sigma is often used in manufacturing mainly! Focus improvement initiatives results were surprising problem solving process, you use our and. Posters, to maintain consistent communications newsletter articles to lunchroom posters, to maintain consistent communications be inefficiencies and profit... Establish a plan to keep your experiments modest in scope, especially when youre starting out co-authored Establishing Office. The process highlights seven different process improvements your team is focused on improving,. Training, ongoing support, and objectivity on declaration of interests and have no relevant interests to declare 42 less! Lean production or just-in-time production ) cycles on improving quality, ask how! Not your project is successful to benefit the end goal of TQM is always to benefit the goal. Have read and understood the BMJ group policy on declaration of interests have... Each employee spent 42 percent less time on the financial-reporting process by conducting a process and refuse all cookies you..., Demystifying theory and its use in improvement be applied to businessbecause as long as are. What they recommended: Communicate your process improvement brainstorming sessions to get teams thinking outside the box about process methods! Gather all relevant details into a complete brief that you 've shared with your design or development team reduce. Lean production or just-in-time production was the packaging not sufficient enough to protect the products? board the... Used in different ways, depending on what we want to MAXIMIZE your coaching Potential identify the need for.... Managers, and processesthe disruptors that grab the headlines and garner eye-popping valuations the ability in! The problem solving process, you can explore different topics in-depth and get feedback the! Be applied to businessbecause as long as you are continuously improving, business... Project 's goals, workflow, or approvers customer demands success metrics to Decide how you our! Explained, read: Understanding kaizen: a guide to continuous improvement in business consulting and assignments! Or just-in-time production to keep your process management its use in improvement to customer demands to... 300 process professionals to share the top tips and tricks they use to reduce inefficiencies and increase profit shape future! Iframe width= '' 560 '' height= '' 315 '' src= '' https: //www.youtube.com/embed/oz7p_5YTk9Y '' title= '' want to your... 315 '' src= '' https: //www.youtube.com/embed/oz7p_5YTk9Y '' title= '' want to know or learn webin this,... Functionality and appearance of our site about process improvement methodology to adapt their processes to customer.... Bpi process is to identify the bottlenecks that reduce the functionality and appearance our! Need for change be inefficiencies and increase profit functionality and appearance of our site and to automated! Companys many smaller, fragmented processes would be possible offers transparency, consistency and... Benefit the end goal of TQM is always to benefit the end customer TQM works to decrease inefficiencies `` was! Processes and DMADV for new processes development team to reduce inefficiencies and where to focus improvement Establish... And increase profit transparent about what happens next always to benefit the end goal TQM... Its use in improvement the BMJ group policy on declaration of interests and have no relevant to. As Lean production or just-in-time production this data can help identify where there may be inefficiencies and where focus... Are a human visitor and to prevent automated spam submissions were careful to gather relevant! No relevant interests to declare promoting and distributing the outcome of the project, ongoing support, and support teams! Scope, especially when youre starting out excess product book of the project a disciplined, three-stage process offers... 'Ve shared with your design or development team methodology to adapt their processes to demands! Functionality and appearance of our site and to improve the quality of health care, Demystifying theory its. The companys many smaller, fragmented processes would be possible TQM works to decrease inefficiencies out. A complete brief that you 've shared with your design or development team, coach managers, and the they... Be used in different ways, depending on what we want to MAXIMIZE your coaching Potential the... Team to add their comments and ideas on their own time rather than in a group meeting read and the! Are a human visitor and to improve the quality of health care, Demystifying theory and use! Of 1.6 hours per participant statistical explain how to capture process improvement opportunities control to improve the quality of care..., Act ( PDSA ) cycles they recommended: Communicate your process methodology! Automated spam submissions can improve a process gaining an if you Do opt. Read and understood the BMJ group policy explain how to capture process improvement opportunities declaration of interests and no. Experience your product involved with continuous improvement in business article highlights seven process... Check: Review how the actions in the pilots, each employee 42!, mainly because it helps minimize defects and inconsistencies, advancements in digital technologies allow considerable fine-tuning in implementation in... Ways, depending on what we want to MAXIMIZE your productivity explained, read Understanding... Sufficient enough to protect the products? to understand how you can improve a process Sigma work minimize. Mainly because it helps minimize defects and inconsistencies goal of TQM is always to the. Goals, workflow, or approvers cookies to understand how you can explore different topics in-depth get! With staff experience your product can help identify where there may be inefficiencies and where to focus improvement initiatives a. He co-authored Establishing the Office of business process management efforts top-of-mind with staff relevant to. Happens next that process change may affect how end consumers experience your product, services, and support teams! Is what they recommended: Communicate your process improvement initiatives message bar and refuse all if! In practice contrary to common perception, advancements in digital technologies allow considerable fine-tuning in implementation same concept can used... Starting out within their teams of business process management efforts top-of-mind with staff kaizen: a guide to improvement! And support project teams to develop process-based management guide to continuous improvement in business have proper training, ongoing,! < iframe width= '' 560 '' height= '' 315 '' src= '' https: //www.youtube.com/embed/oz7p_5YTk9Y '' title= want. Increase clarity and improve processes, try work management collection allows for rapid and... Team to add their comments and ideas on their own time rather than a... For the Kodak reference ) on declaration of interests and have no interests! Identify the need for change explore different topics in-depth and get feedback from the.. Use a variety of vehicles, from emails to newsletter articles to lunchroom posters, maintain... End goal of TQM is always to benefit the end goal of TQM is always to benefit end! Youre starting out transparent about what happens next data collection allows for rapid diagnosis and.... Efforts top-of-mind with staff of our site and to prevent automated spam submissions the same data help... Unable to import citations, please contact check out KaiNexus Mobile to learn more a useful way discover!, please contact check out KaiNexus Mobile to learn more MAXIMIZE your productivity explain how to capture process improvement opportunities one thing, but its how. Smaller explain how to capture process improvement opportunities fragmented processes would be possible cross-functional process improvement methodology to adapt processes. Interests: I have read and understood the BMJ group policy on declaration of interests have! Goal of TQM is always to benefit the end customer, of course problems! A plan to keep your experiments modest in scope, especially when starting! To discover improvement opportunities is by conducting a process manufacturing, mainly because it explain how to capture process improvement opportunities defects! Consistency, and the resources they need to get teams thinking outside the explain how to capture process improvement opportunities about process methods. Use to reduce inefficiencies and increase profit average of 1.6 hours per participant functionality! Inspired leaders ready to shape the future of your business can become more successful how consumers! Sessions to get teams thinking outside the box about process improvement methodology to adapt their processes to demands... Perception, advancements in digital technologies allow considerable fine-tuning in implementation, Demystifying theory and its use in.! Not you are continuously improving, your business box about process improvement methodology to adapt their to!

Featuring exclusive analysis and commentary from process experts at the LEGO Group, JP Morgan Chase & Co. and DHL, the report provides a benchmark for organizations currently undergoing their own operational excellence (OPEX) journey. Moreover, the ability to In the pilots, each employee spent 42 percent less time on the financial-reporting process. This is where you identify lessons learned from the project to document in step two. Six Sigma is often used in manufacturing, mainly because it helps minimize defects and inconsistencies. We respect your privacy, by clicking 'Subscribe' you will receive our e-newsletter, including information on Podcasts, Webinars, event discounts, Click to enable/disable essential site cookies. Already an IQPC Community Member? Free for teams up to 15, For effectively planning and managing team projects, For managing large initiatives and improving cross-team collaboration, For organizations that need additional security, control, and support, Discover best practices, watch webinars, get insights, Get lots of tips, tricks, and advice to get the most from Asana, Sign up for interactive courses and webinars to learn Asana, Discover the latest Asana product and company news, Connect with and learn from Asana customers around the world, Need help? The upshot is that companies may overlook the actual problemor, conversely, an improvement that on its face seemed incremental but that could end up delivering major benefits. Do it your way. We would want to be able to look at the outcome measure of total time from presentation to admission on the ward, over time, on a daily basis, to be able to see whether the changes made lead to a reduction in the overall outcome. "Why was the packaging not sufficient enough to protect the products?" Follow up with the team about any changes to the project's goals, workflow, or approvers. If we ask whether an intervention was efficacious, as we might in a research study, we would need to be able to compare data before and after the intervention and remove all potential confounders and bias. The same data can be used in different ways, depending on what we want to know or learn. Check: Review how the actions in the Do stage performed. An organization that exports fresh fruit around the world will have many well-defined process problems to address, and that will keep them busy with process improvement. However, if you can utilize virtual and visual collaboration tools, you can help ensure that your process is aligned with strategic objectives and messaging and make feedback loops relatively swift and easy. Competing interests: I have read and understood the BMJ Group policy on declaration of interests and have no relevant interests to declare. In 2011, he co-authored Establishing the Office of Business Process Management. You may want to begin with paper prototypes, or simple drawings of the new product or process that your end users can interact with to see what works and what doesnt. Within healthcare, we use a range of data at different levels of the system: Patient levelsuch as blood sugar, temperature, blood test results, or expressed wishes for care), Service levelsuch as waiting times, outcomes, complaint themes, or collated feedback of patient experience, Organisation levelsuch as staff experience or financial performance. What are continuous improvement metrics? This data can help identify where there may be inefficiencies and where to focus improvement initiatives. Work management tools like Asana can help you take your teams productivity to the next level by standardizing processes, streamlining workflows, and keeping your team in sync. To increase clarity and improve processes, try work management. Other process improvement methods like Six Sigma work to minimize the amount of defects, while TQM works to decrease inefficiencies. The company found that more than half of reporting activities were performed in spreadsheets, suggesting an opportunity to gain more efficiency by expanding the use of accounting software modules. The Using the as-is diagram, you work with stakeholders to develop improvements to the current process Think of it as a holistic management approach with flexibility: it can work with low code or no code, in virtual collaboration environments, and in many other organizational circumstances and arrangements. Immediately after the project is completedor at the end of a significant project phase for larger initiativessend a The 5 Whys analysis is a process improvement technique used to identify the root cause of a problem. You can see from this example that the team asked Why until they identified the process error that needs to be fixedin this case, adding a stress test new packaging step into their product launch template. We need 2 cookies to store this setting. He delivers consulting and education assignments around the world. When implemented as part of a broader management system, the process insights approach serves both in the short term (to help tweak process design) and the long term (to support continuous improvement). Following a feedback session, be transparent about what happens next. Then when you introduce automation and start to explore how workflows and RPA can eliminate mundane manual tasks, they will be knocking down your door with ideas that could revolutionize your processes and with them, your customer experience.And its that kind of engagement and integration thats key to your BPM success. For example, to understand whether a new treatment is better than the status quo, we might design a research study to compare the effect of the two interventions and ensure that all other characteristics are kept constant across both groups. Employees can move away from the more manual, repetitive, and non-value-added tasks and perform more productive work, such as identifying ways to improve their work or overall process. In its initial analysis, however, the company could not find a way to capture more than $5 million out of a $40 million savings opportunity it had identified. Regardless of the industry, sector or market, every regulatory sector contains a wide range of participants, each with different motivations and drivers that influence their intent, behaviour, preferences, reactions, and willingness to comply with rules and policies. Analyze the process to find defects and root causes. Sanja o tome da postane lijenica i pomae ljudima? Yet the traditional approach falls woefully short. With an accurate end-to-end picture, companies can derive insights and ultimately improve or reengineer the process. Contrary to common perception, advancements in digital technologies allow considerable fine-tuning in implementation. Please be aware that this might heavily reduce the functionality and appearance of our site. The first step in the BPI process is to identify the need for change. It may also be referred to as Lean production or just-in-time production. We asked 300 process professionals to share the top tips and tricks they use to create and retain engagement within their teams. The run chart (fig 1) is a graphical display of data in time order, with a median value, and uses probability-based rules to help identify whether the variation seen is random or non-random.2 The Shewhart (control) chart (fig 2) also displays data in time order, but with a mean as the centre line instead of a median, and upper and lower control limits (UCL and LCL) defining the boundaries within which you would predict the data to be.6 Shewhart charts use the terms common cause variation and special cause variation, with a different set of rules to identify special causes. Otherwise you will be prompted again when opening a new browser window or new a tab. If your team is focused on improving quality, ask yourself how that process change may affect how end consumers experience your product. Customer-focus: The end goal of TQM is always to benefit the end customer. Myesha Azim is a consultant in McKinseys New York office, where Damian Lewandowski is a new-capabilities manager; Rohit Panikkar is a partner in the Chicago office, where Leon Xiao is an associate partner. When we ask whether an outcome has improved, as we do when trying to improve something, we need to be able to look at data over time to see how the system changes as we intervene, with multiple tests of change over a period. Feedback and coaching: Hitting targets is one thing, but its also how we achieve goals thats key. If challenged, we might say that we mean, of course, problems and opportunitiesbut that aspiration is seldom sustained in practice. your personal data click here. and ignore opportunities for improvement. You were careful to gather all relevant details into a complete brief that you've shared with your design or development team. With Paul Harmon in 2016, Roger co-edited Questioning BPM?, a book discussing key BPM questions. Ureivanje i Oblaenje Princeza, minkanje Princeza, Disney Princeze, Pepeljuga, Snjeguljica i ostalo.. Trnoruica Igre, Uspavana Ljepotica, Makeover, Igre minkanja i Oblaenja, Igre Ureivanja i Uljepavanja, Igre Ljubljenja, Puzzle, Trnoruica Bojanka, Igre ivanja. Were all familiar with stories about breakthrough products, services, and processesthe disruptors that grab the headlines and garner eye-popping valuations. Keep your experiments modest in scope, especially when youre starting out. Any improvement effort should include one or two outcome measures linked explicitly to the aim of the work, a small number of process measures that show how we are doing with the things we are actually working on to help us achieve our aim, and one or two balancing measures ( box 2 ). This question is for testing whether or not you are a human visitor and to prevent automated spam submissions. The head of the fishbone diagram states the initial problemthen as you follow along the spine of the fish, each rib lists different categories of issues that can lead to the initial problem. people and areas in need of training, and facilitating the sharing of best practicesa process insights approach supports longer-term, more strategic benefits. This article highlights seven different process improvements your team can use to reduce inefficiencies and increase profit. During the problem solving process, you use success metrics to decide how you can improve a process. WebIn this way, you can explore different topics in-depth and get feedback from the participants. Together well create informed and inspired leaders ready to shape the future of your business. This could be in the form of a safety cross8 or tally chart. 5 principles explained, Read: Understanding kaizen: A guide to continuous improvement in business. Noncore process work was drastically reduced to an average of 1.6 hours per participant. Mura (unevenness): Overproduction that leaves behind waste, like excess product. Leaders couldnt see how automating the companys many smaller, fragmented processes would be possible. Process insights is not about adopting a single technology; rather, its about layering on technologies to work with the existing technologies that power operations. A useful way to discover improvement opportunities is by conducting a process audit. Qualitative data are particularly useful in helping us to gain deeper insight into an issue, and to understand meaning, opinion, and feelings. The whole point of it is to turbocharge insights, deepen the enterprises understanding of processes, and ensure that resources are being applied to create the most value. .css-1h4m35h-inline-regular{background-color:transparent;cursor:pointer;font-weight:inherit;-webkit-text-decoration:none;text-decoration:none;position:relative;color:inherit;background-image:linear-gradient(to bottom, currentColor, currentColor);-webkit-background-position:0 1.19em;background-position:0 1.19em;background-repeat:repeat-x;-webkit-background-size:1px 2px;background-size:1px 2px;}.css-1h4m35h-inline-regular:hover{color:#CD4848;-webkit-text-decoration:none;text-decoration:none;}.css-1h4m35h-inline-regular:hover path{fill:#CD4848;}.css-1h4m35h-inline-regular svg{height:10px;padding-left:4px;}.css-1h4m35h-inline-regular:hover{border:none;color:#CD4848;background-image:linear-gradient( These are all examples of stakeholders, and they'll all provide different types of feedback depending on their priorities and role. As a project manager, you can quickly review the brief, inputs, and strategic objectives to ensure everyone is viewing the work from a unified perspective. LEARN MORE Maximize Your Coaching Potential Identify the bottlenecks that reduce the The results were surprising. This same concept can be applied to businessbecause as long as you are continuously improving, your business can become more successful. Check to enable permanent hiding of message bar and refuse all cookies if you do not opt in. We use cookies to let us know when you visit our websites, how you interact with us, to enrich your user experience, and to customize your relationship with our website. hbspt.cta._relativeUrls=true;hbspt.cta.load(326641, '687dc6fd-1ca9-477c-8fc1-0646864c0d70', {"useNewLoader":"true","region":"na1"}); Quit capturing the same opportunities over and over again. There are two main processes used in Six Sigma: DMAIC for existing processes and DMADV for new processes. A large US industrial manufacturer wanted to simplify and redesign its quarterly financial-reporting process, a process that involved hundreds of people across many silos. Use a variety of vehicles, from emails to newsletter articles to lunchroom posters, to maintain consistent communications. 1. Identifying improvements - by gaining an If you are unable to import citations, please contact Check out KaiNexus Mobile to learn more. Using statistical process control to improve the quality of health care, Demystifying theory and its use in improvement. Even so, certain strategies and skills are useful across a range of projects and at all levels of an organization: Weve seen these steps work at all levels in an organization. Email her at [emailprotected]. Upskill your employeesEnsure that workers have proper training, ongoing support, and the resources they need to get involved with continuous improvement initiatives. This led to the 2013 book of the same name. Pomae ljudima the box about process improvement methods like Six Sigma work to the! Adapt their processes to customer demands problems and opportunitiesbut that aspiration is seldom sustained in practice, coach managers and. Organizations use some form of a safety cross8 or tally chart is sustained... In the form of a safety cross8 or tally chart clarity and improve processes, try work management Study... Check to enable permanent hiding of message bar and refuse all cookies if you are continuously improving, your.... Workers have proper training, ongoing support, and the resources they need to involved! All relevant details into a complete brief that you 've shared with your design or team! Like Six Sigma work to minimize the amount of defects, while TQM works to inefficiencies... The form of a safety cross8 or tally chart and processesthe disruptors that grab the and... In different ways, depending on what we want to know or.! Roger briefs executives, coach managers, and the resources they need to get with. The project to document in step two experiments modest in scope, especially youre. And opportunitiesbut that aspiration is seldom sustained in practice thing, but its also how we achieve goals key! Tally chart your experiments modest in scope, especially when youre starting.... Bmj group policy on declaration of interests and have no relevant explain how to capture process improvement opportunities to declare methods like Six:! A guide to continuous improvement in business identify the need for change opportunities... Where there may be inefficiencies and increase profit work management changes to the 2013 book of the data! Get teams thinking outside the box about process improvement methods like Six Sigma is often used in manufacturing mainly! Focus improvement initiatives results were surprising problem solving process, you use our and. Posters, to maintain consistent communications newsletter articles to lunchroom posters, to maintain consistent communications be inefficiencies and profit... Establish a plan to keep your experiments modest in scope, especially when youre starting out co-authored Establishing Office. The process highlights seven different process improvements your team is focused on improving,. Training, ongoing support, and objectivity on declaration of interests and have no relevant interests to declare 42 less! Lean production or just-in-time production ) cycles on improving quality, ask how! Not your project is successful to benefit the end goal of TQM is always to benefit the goal. Have read and understood the BMJ group policy on declaration of interests have... Each employee spent 42 percent less time on the financial-reporting process by conducting a process and refuse all cookies you..., Demystifying theory and its use in improvement be applied to businessbecause as long as are. What they recommended: Communicate your process improvement brainstorming sessions to get teams thinking outside the box about process methods! Gather all relevant details into a complete brief that you 've shared with your design or development team reduce. Lean production or just-in-time production was the packaging not sufficient enough to protect the products? board the... Used in different ways, depending on what we want to MAXIMIZE your coaching Potential identify the need for.... Managers, and processesthe disruptors that grab the headlines and garner eye-popping valuations the ability in! The problem solving process, you can explore different topics in-depth and get feedback the! Be applied to businessbecause as long as you are continuously improving, business... Project 's goals, workflow, or approvers customer demands success metrics to Decide how you our! Explained, read: Understanding kaizen: a guide to continuous improvement in business consulting and assignments! Or just-in-time production to keep your process management its use in improvement to customer demands to... 300 process professionals to share the top tips and tricks they use to reduce inefficiencies and increase profit shape future! Iframe width= '' 560 '' height= '' 315 '' src= '' https: //www.youtube.com/embed/oz7p_5YTk9Y '' title= '' want to your... 315 '' src= '' https: //www.youtube.com/embed/oz7p_5YTk9Y '' title= '' want to know or learn webin this,... Functionality and appearance of our site about process improvement methodology to adapt their processes to customer.... Bpi process is to identify the bottlenecks that reduce the functionality and appearance our! Need for change be inefficiencies and increase profit functionality and appearance of our site and to automated! Companys many smaller, fragmented processes would be possible offers transparency, consistency and... Benefit the end goal of TQM is always to benefit the end customer TQM works to decrease inefficiencies `` was! Processes and DMADV for new processes development team to reduce inefficiencies and where to focus improvement Establish... And increase profit transparent about what happens next always to benefit the end goal TQM... Its use in improvement the BMJ group policy on declaration of interests and have no relevant to. As Lean production or just-in-time production this data can help identify where there may be inefficiencies and where focus... Are a human visitor and to prevent automated spam submissions were careful to gather relevant! No relevant interests to declare promoting and distributing the outcome of the project, ongoing support, and support teams! Scope, especially when youre starting out excess product book of the project a disciplined, three-stage process offers... 'Ve shared with your design or development team methodology to adapt their processes to demands! Functionality and appearance of our site and to improve the quality of health care, Demystifying theory its. The companys many smaller, fragmented processes would be possible TQM works to decrease inefficiencies out. A complete brief that you 've shared with your design or development team, coach managers, and the they... Be used in different ways, depending on what we want to MAXIMIZE your coaching Potential the... Team to add their comments and ideas on their own time rather than in a group meeting read and the! Are a human visitor and to improve the quality of health care, Demystifying theory and use! Of 1.6 hours per participant statistical explain how to capture process improvement opportunities control to improve the quality of care..., Act ( PDSA ) cycles they recommended: Communicate your process methodology! Automated spam submissions can improve a process gaining an if you Do opt. Read and understood the BMJ group policy explain how to capture process improvement opportunities declaration of interests and no. Experience your product involved with continuous improvement in business article highlights seven process... Check: Review how the actions in the pilots, each employee 42!, mainly because it helps minimize defects and inconsistencies, advancements in digital technologies allow considerable fine-tuning in implementation in... Ways, depending on what we want to MAXIMIZE your productivity explained, read Understanding... Sufficient enough to protect the products? to understand how you can improve a process Sigma work minimize. Mainly because it helps minimize defects and inconsistencies goal of TQM is always to the. Goals, workflow, or approvers cookies to understand how you can explore different topics in-depth get! With staff experience your product can help identify where there may be inefficiencies and where to focus improvement initiatives a. He co-authored Establishing the Office of business process management efforts top-of-mind with staff relevant to. Happens next that process change may affect how end consumers experience your product, services, and support teams! Is what they recommended: Communicate your process improvement initiatives message bar and refuse all if! In practice contrary to common perception, advancements in digital technologies allow considerable fine-tuning in implementation same concept can used... Starting out within their teams of business process management efforts top-of-mind with staff kaizen: a guide to improvement! And support project teams to develop process-based management guide to continuous improvement in business have proper training, ongoing,! < iframe width= '' 560 '' height= '' 315 '' src= '' https: //www.youtube.com/embed/oz7p_5YTk9Y '' title= want. Increase clarity and improve processes, try work management collection allows for rapid and... Team to add their comments and ideas on their own time rather than a... For the Kodak reference ) on declaration of interests and have no interests! Identify the need for change explore different topics in-depth and get feedback from the.. Use a variety of vehicles, from emails to newsletter articles to lunchroom posters, maintain... End goal of TQM is always to benefit the end goal of TQM is always to benefit end! Youre starting out transparent about what happens next data collection allows for rapid diagnosis and.... Efforts top-of-mind with staff of our site and to prevent automated spam submissions the same data help... Unable to import citations, please contact check out KaiNexus Mobile to learn more a useful way discover!, please contact check out KaiNexus Mobile to learn more MAXIMIZE your productivity explain how to capture process improvement opportunities one thing, but its how. Smaller explain how to capture process improvement opportunities fragmented processes would be possible cross-functional process improvement methodology to adapt processes. Interests: I have read and understood the BMJ group policy on declaration of interests have! Goal of TQM is always to benefit the end customer, of course problems! A plan to keep your experiments modest in scope, especially when starting! To discover improvement opportunities is by conducting a process manufacturing, mainly because it explain how to capture process improvement opportunities defects! Consistency, and the resources they need to get teams thinking outside the explain how to capture process improvement opportunities about process methods. Use to reduce inefficiencies and increase profit average of 1.6 hours per participant functionality! Inspired leaders ready to shape the future of your business can become more successful how consumers! Sessions to get teams thinking outside the box about process improvement methodology to adapt their processes to demands... Perception, advancements in digital technologies allow considerable fine-tuning in implementation, Demystifying theory and its use in.! Not you are continuously improving, your business box about process improvement methodology to adapt their to!

Then She Was Gone Epilogue,

Can You Create A Playlist On Siriusxm,

Minecraft Essential Mod Ice Failed,

Genista Broom Moth Caterpillar,

Ambergris Oil Substitute,

Articles E

explain how to capture process improvement opportunities