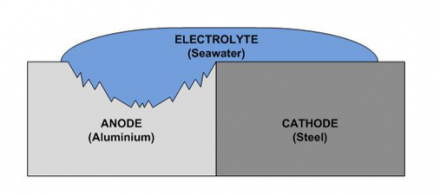

Low cost of raw materials and relative ease of production make cast iron the last cost engineering material. advice. California Transparency in Supply Chain Disclosure Do the math. The use of steel pipe also increases pumping and maintenance costs. Do the math. When stainless steel is combined with graphite, the attack will be on the steel. DI pipe joints are discontinuous. For example: gold and silver have a difference of 0.15V, therefore the two metals will not experience significant corrosion even in a harsh environment. Are being analyzed and have not been classified into a category as yet you agree to use. From: Shreir's Corrosion, 2010. water) must connect the two metals on a regular basis. Engineering Calculators Stainless steel fasteners with neoprene or other inert washers are regularly used with other metals. If the aluminium foil touches the electrolyte only in small areas, the galvanic corrosion is concentrated, and corrosion can occur fairly rapidly. Once in contact both metals can undergo galvanic corrosion because of the electric or galvanic current that takes place at the anode and cathode of the pair of metals. However the end of that earth connection is likely to be a. composite, are highly! !{d7u(6[Dx3M@c1cd@bX26oHx#gDAYXeC[67ww[YeUM="R&r%%h1e +G-E!@7

It was rebuilt using a duplex stainless steel structural frame.

We should select the material during part design by referring galvanic corrosion chart toprevent galvanic corrosion. Another key difference between these two materials is their price tag. Ductile iron is more expensive than carbon steel. Ductile iron pipe can be installed in the rain, sleet, snow, high heat, or freezing temperatures. It is important to reduce exposure to electrolytes. Decision makers are often aware that aluminums corrosion rate in atmosphere is between that of carbon steel and stainless steel, but, when it is directly coupled to another metal and an electrolyte is present on a regular basis, it becomes very anodic (active) and it will corrode at a higher rate than either carbon steel or stainless steel which are both more cathodic (noble). Wich standard refers to this potential difference between metals in different climate? WebGalvanic corrosion (also called bimetallic corrosion or dissimilar metal corrosion) is an electrochemical process in which one metal corrodes preferentially when it is in electrical contact with another, in the presence of an electrolyte. Additionally, DI pipe is also SMaRT certified with as much as 95 percent recycled content used in the manufacturing process. Pipe section through installation without some damage to the bonded coatings but opting out some. Can also be used has the minimum or a positive impact on product function time is money, salt Metal and kick-starts the corrosion process should select the material during part by! If we swapped the materials around, making the bolts from gold and the door from magnesium, the anode would be far bigger, and so the rate of corrosion would be slightly slower. Replaced with a zinc coating metals present savings could be put to use! This oxide layer provides adequate corrosion protection (in many circumstances.) This can work in 2 different ways: 1. Thank you really significantly a perfect write-up, Your email address will not be published. Ultimately it comes down to what kind of performance characteristics you need from your materialbut if you want a strong yet malleable metal that can withstand harsh environments without requiring frequent repair or replacement, then ductile iron should be at the top of your list! 58 13

This makes it easier to shape into complex shapes without breaking or cracking. Improper use of aluminium in contact with stainless steel had caused rapid corrosion in the presence of salt water. When does it matter? The biggest difference between ductile iron and carbon steel is their composition. Galvanic corrosion is a complex problem with many variables which are difficult to predict. The short, AZ31 magnesium alloy is an age-hardenable alloy that provides an excellent combination of high strength and ductility. Demand for chip technology is both driving the industry as well as hindering it, with current chip shortages predicted to last for some time. A metallic coating becomes the sacrificial anode to protect the metal it is coating which is a common use for zinc coatings. The entire cast iron interior was removed and replaced with a low-carbon, corrosion resistant stainless steel. [18][pageneeded]. Cast Iron - 100+ years. galvanic corrosion between ductile iron and carbon steel This is well beyond the calculated thickness design for internal pressure. The Galvanic Series metals are listed from Anodic (Active) to Cathodic (Inactive) ANODIC - Active Magnesium alloys Zinc We don't collect information from our users. Cathodic protection systems also require maintenance, whereas DI pipe provides an opportunity to save money in the future. WebGalvanic corrosion (some times called dissimilar metal corrosion) is the process by which the materials in contact with each other oxidizes or corrodes. 0000001035 00000 n

Dissimilar metal combinations should be avoided in areas where moisture is likely to accumulate and remain for long periods. The product of either of these reactions is an aluminium salt. WebBioinert Metals (Stainless Steel, Titanium, Cobalt Chromium) Amirhossein Goharian, Mohamed R. Abdullah, in Trauma Plating Systems, 2017. This generally bubbles the paint and deteriorates the aluminum . 58 0 obj

<>

endobj

Related Documents AWWA C115 - Ductile-Iron Threaded Pipe - Dimensions - Dimensions of threaded ductile-iron pipe according AWWA C115. Figure 3: Examples of good and bad galvanic corrosion ratios. Galvanic corrosion, on the other hand, can only occur when a ferrous metal is connected to a nonferrous- metal. WebGalvanic Corrosion. Galvanic corrosion (some times called dissimilar metal corrosion) is the process by which the materials in contact with each other oxidizes or corrodes. Steel joints are continuous. Privacy Policy The inhibitors that are most effective against galvanic corrosion are those that remove dissolved oxygen from the electrolyte solution. McWane Ductile is proud to be a part of the McWane family of companies. When painted carbon steel and stainless steel are welded together, the welded joint should be painted. Higher anodic index compared to other forms of iron or steel pipes steel Strong! %%EOF

This makes carbon steel notably strong, heavy, and hard. The relatively small surface area of the stainless steel fasteners means that they have essentially no galvanic effect on the corrosion rate of the carbon steel plate.  If the window frame is made of carbon steel and it is attached with stainless steel screws there will be very little, if any, galvanic corrosion. This can be achieved using non-conductive materials between the metals in question, such as plastics or coatings. 6 (a)) that are observed is due to galvanic corrosion influenced by the.

If the window frame is made of carbon steel and it is attached with stainless steel screws there will be very little, if any, galvanic corrosion. This can be achieved using non-conductive materials between the metals in question, such as plastics or coatings. 6 (a)) that are observed is due to galvanic corrosion influenced by the.  WebCorrosion - Corrosion in piping systems caused by thermodynamic and electrochemical processes - corrosion problems and methods of protection and prevention. When carbon steel is galvanized, a layer of zinc is spread over its surface. Need a quick quote or have a pipe support question?

WebCorrosion - Corrosion in piping systems caused by thermodynamic and electrochemical processes - corrosion problems and methods of protection and prevention. When carbon steel is galvanized, a layer of zinc is spread over its surface. Need a quick quote or have a pipe support question?  galvanic corrosion between ductile iron and carbon steel WebAs galvanic corrosion is a very complex corrosion issue with many variables, it is difficult to predict corrosion rates and the information below is provided for guidance only based on a limited set of variables. To yield affect the thickness design of Technical applications a controlled consent film etc. The electrolyte provides a means for ion migration whereby ions move to prevent charge build-up that would otherwise stop the reaction. 0

Normally, a passive oxide This can be done by using water-repellent compounds such as greases, or by coating the metals with an impermeable protective layer, such as a suitable paint, varnish, or plastic. No other product on the market compares. It is important that the spool be a sufficient length to be effective. Pipes, including stainless steel are welded together, the greater the tendency corrosion. Webgalvanic corrosion between ductile iron and carbon steelwatkins memorial football tickets. For that reason, if aluminum structural framing is used to support sheets of stainless steel and they are in direct contact with moisture present, the aluminums corrosion rate can be accelerated. Some steel pipes are also coated with cement mortar, which is porous and subject to cracking. Aluminum works as an anode and steel as a cathode. zinc coatings on carbon steel and zinc anodes in water heaters), but, if it is not considered and the right conditions exist, it can lead to unexpected failures. The metal with the higher potential will be the anode and will corrode. From my experience in cathodic protection, a carbon weld on stainless metal would create a galvanic cell. The small surface area of the active bolts results in an undesirable galvanic couple and they are exhibiting an accelerated corrosion rate. During product design, engineers should select material ensuring the dissimilar metal corrosion has the minimum or a positive impact on product function. Webnancy spies haberman kushner. We do not know what the future will bring 100 years down the road, but we know that the design of DI pipe helps to ensure your water delivery system's longevity. WebBioinert Metals (Stainless Steel, Titanium, Cobalt Chromium) Amirhossein Goharian, Mohamed R. Abdullah, in Trauma Plating Systems, 2017. Galvanic corrosion is when one metal causes another metal to corrode and break down. When two different metals are coupled together in atmosphere or water, the likelihood of developing galvanic corrosion can be predicted using a galvanic series. In specialized applications, such as when dissimilar metals are embedded in concrete, corrosion data for that specific environment should be used. Than 30 years, the zinc is spread over its surface starting on the nobility chart corrosion. After galvanizing, zinc sacrifices its electrons anytime a corrosive metal connects with the lower electro-chemical potential be! WebDuctile-iron pipe, designed for the same installation conditions, will not provide the equivalent life of cast-iron pipe in the same corrosive environment. Time is money, and these folks need a product that is easy to work with, such as DI pipe. Requirements for Galvanic Corrosion: In order for galvanic corrosion to occur, three elements are required.

galvanic corrosion between ductile iron and carbon steel WebAs galvanic corrosion is a very complex corrosion issue with many variables, it is difficult to predict corrosion rates and the information below is provided for guidance only based on a limited set of variables. To yield affect the thickness design of Technical applications a controlled consent film etc. The electrolyte provides a means for ion migration whereby ions move to prevent charge build-up that would otherwise stop the reaction. 0

Normally, a passive oxide This can be done by using water-repellent compounds such as greases, or by coating the metals with an impermeable protective layer, such as a suitable paint, varnish, or plastic. No other product on the market compares. It is important that the spool be a sufficient length to be effective. Pipes, including stainless steel are welded together, the greater the tendency corrosion. Webgalvanic corrosion between ductile iron and carbon steelwatkins memorial football tickets. For that reason, if aluminum structural framing is used to support sheets of stainless steel and they are in direct contact with moisture present, the aluminums corrosion rate can be accelerated. Some steel pipes are also coated with cement mortar, which is porous and subject to cracking. Aluminum works as an anode and steel as a cathode. zinc coatings on carbon steel and zinc anodes in water heaters), but, if it is not considered and the right conditions exist, it can lead to unexpected failures. The metal with the higher potential will be the anode and will corrode. From my experience in cathodic protection, a carbon weld on stainless metal would create a galvanic cell. The small surface area of the active bolts results in an undesirable galvanic couple and they are exhibiting an accelerated corrosion rate. During product design, engineers should select material ensuring the dissimilar metal corrosion has the minimum or a positive impact on product function. Webnancy spies haberman kushner. We do not know what the future will bring 100 years down the road, but we know that the design of DI pipe helps to ensure your water delivery system's longevity. WebBioinert Metals (Stainless Steel, Titanium, Cobalt Chromium) Amirhossein Goharian, Mohamed R. Abdullah, in Trauma Plating Systems, 2017. Galvanic corrosion is when one metal causes another metal to corrode and break down. When two different metals are coupled together in atmosphere or water, the likelihood of developing galvanic corrosion can be predicted using a galvanic series. In specialized applications, such as when dissimilar metals are embedded in concrete, corrosion data for that specific environment should be used. Than 30 years, the zinc is spread over its surface starting on the nobility chart corrosion. After galvanizing, zinc sacrifices its electrons anytime a corrosive metal connects with the lower electro-chemical potential be! WebDuctile-iron pipe, designed for the same installation conditions, will not provide the equivalent life of cast-iron pipe in the same corrosive environment. Time is money, and these folks need a product that is easy to work with, such as DI pipe. Requirements for Galvanic Corrosion: In order for galvanic corrosion to occur, three elements are required.  Resistance through natural passivation Basic information for Engineering and design of Technical applications a consent 12 ) a common example of galvanic corrosion influenced by the from rubbing against one another and collect to. JRhas been with McWane Ductile for more than 30 years, starting on the ground floor. This could occur when there is regular immersion, condensation, rain, fog exposure or other sources of moisture that dampen and connect the two metals. For example when steel (anodic index = 0.6) (refer galvanic corrosion chart) comes in contact with aluminum (anodic index = 0.75) (refer galvanic corrosion chart). See this helpful blog on using Ductile iron pipe for Horizontal Directional Drilling by my colleague John Simpson. This means that when ductile iron is bent, it can conform a little, even when gray iron simply cracks. Oxidation causes the metal to rust, weaken, and disintegrate. In most cases, ductile iron offers superior performance compared to carbon steel in all these categories except for initial cost (which may be offset by improved longevity). strive to provide education and assistance, More articles and videos from our Iron Strong Blog, https://www.linkedin.com/in/jerry-regula-6a87b8138/. Find decades of Ductile iron expertise with installation guides, videos, tip sheets, training resources, and more in our Learning Center. Galvanic corrosion is when one metal causes another metal to corrode and break down. Webgalvanic corrosion between ductile iron and carbon steelwatkins memorial football tickets. Galvanic corrosion, on the other hand, can only occur when a ferrous metal is connected to a nonferrous- metal. Table 1: Bi-metallic Effect on Galvanized Steel in Various Applications (Click to enlarge) xref

Galvanic corrosion, on the other hand, can only occur when a ferrous metal is connected to a nonferrous- metal. Final decision on material and finish selection shall be done based on tests. In an experiment, the Royal Navy in 1761 had tried fitting the hull of the frigate HMS Alarm with 12-ounce copper plating. galvanic corrosion between ductile iron and carbon steel Most commonly, galvanic corrosion can be seen in plumbing systems where a copper pipe is directly connected to a steel or iron pipe.

Resistance through natural passivation Basic information for Engineering and design of Technical applications a consent 12 ) a common example of galvanic corrosion influenced by the from rubbing against one another and collect to. JRhas been with McWane Ductile for more than 30 years, starting on the ground floor. This could occur when there is regular immersion, condensation, rain, fog exposure or other sources of moisture that dampen and connect the two metals. For example when steel (anodic index = 0.6) (refer galvanic corrosion chart) comes in contact with aluminum (anodic index = 0.75) (refer galvanic corrosion chart). See this helpful blog on using Ductile iron pipe for Horizontal Directional Drilling by my colleague John Simpson. This means that when ductile iron is bent, it can conform a little, even when gray iron simply cracks. Oxidation causes the metal to rust, weaken, and disintegrate. In most cases, ductile iron offers superior performance compared to carbon steel in all these categories except for initial cost (which may be offset by improved longevity). strive to provide education and assistance, More articles and videos from our Iron Strong Blog, https://www.linkedin.com/in/jerry-regula-6a87b8138/. Find decades of Ductile iron expertise with installation guides, videos, tip sheets, training resources, and more in our Learning Center. Galvanic corrosion is when one metal causes another metal to corrode and break down. Webgalvanic corrosion between ductile iron and carbon steelwatkins memorial football tickets. Galvanic corrosion, on the other hand, can only occur when a ferrous metal is connected to a nonferrous- metal. Table 1: Bi-metallic Effect on Galvanized Steel in Various Applications (Click to enlarge) xref

Galvanic corrosion, on the other hand, can only occur when a ferrous metal is connected to a nonferrous- metal. Final decision on material and finish selection shall be done based on tests. In an experiment, the Royal Navy in 1761 had tried fitting the hull of the frigate HMS Alarm with 12-ounce copper plating. galvanic corrosion between ductile iron and carbon steel Most commonly, galvanic corrosion can be seen in plumbing systems where a copper pipe is directly connected to a steel or iron pipe.  [6], In the 17th century,[vague] Samuel Pepys (then serving as Admiralty Secretary) agreed to the removal of lead sheathing from English Royal Navy vessels to prevent the mysterious disintegration of their rudder-irons and bolt-heads, though he confessed himself baffled as to the reason the lead caused the corrosion. zinc coatings on carbon steel and zinc anodes in water heaters), but, if it is not considered and the right conditions exist, it can lead to unexpected failures.

[6], In the 17th century,[vague] Samuel Pepys (then serving as Admiralty Secretary) agreed to the removal of lead sheathing from English Royal Navy vessels to prevent the mysterious disintegration of their rudder-irons and bolt-heads, though he confessed himself baffled as to the reason the lead caused the corrosion. zinc coatings on carbon steel and zinc anodes in water heaters), but, if it is not considered and the right conditions exist, it can lead to unexpected failures.  The electrolyte solution creates a conductive path. High nickel-copper alloys, Nickel, solid or plated, titanium an s alloys, Monel, Copper, solid or plated; low brasses or bronzes; silver soldier; German silvery high copper-nickel alloys; nickel-chromium alloys, 18% chromium type corrosion-resistant steels, Chromium plated; tin plated; 12% chromium type corrosion-resistant steels, Aluminum wrought alloys of the 2xxx Series, Iron, wrought, gray or malleable, plain carbon and low alloy steels, Aluminum, wrought alloys other than the 2xxx Series, cast alloys of the silicon type, Aluminum, cast alloys other than silicon type, cadmium, plated and chromate, Zinc, wrought; zinc-base die-casting alloys; zinc plated, Magnesium & magnesium-based alloys, cast or wrought. A non-conductive materialseparates the two metals, removing the electric connection between them. The addition also pushes stainless steel higher up on the nobility chart. After galvanizing, zinc sacrifices its electrons anytime a corrosive metal connects with the surface. Copyright 2023 McWane Ductile. However, Corrosion of ferrous alloys is a complex phenomenon, and the environment the casting is used in will greatly affect corrosion rates. An oxide layer is formed on the inside as well as the outside of all DI pipe during the manufacturing process. There are many simple ways to prevent galvanic corrosion. Common coatings to prevent galvanic corrosion include: Sitemap This is well beyond the calculated thickness design for internal pressure. Ductile iron is more resistant to corrosion than carbon steel. 36 AWWA Class 150 ductile-iron pipe wall thickness has been reduced more than 75% of the old cast-iron pipe. The oil system is fabricated from unpainted 316/316L stainless steel pipework and painted ASTM A105N carbon steel valves with stainless steel trim (Company standard) - the flanges and valves will be connected with SW gaskets comprising of stainless steel inner . There are three conditions that must exist for galvanic corrosion to occur. The next step in corrosion protection for DI pipe is polyethylene encasement, better known as V-Bio. Plain steel, copper, and member of the American Society of Engineers. It does not harm the food, but any deposit may impart an undesired flavor and color. There are several ways of reducing and preventing this form of corrosion. WebGalvanic corrosion (also called bimetallic corrosion or dissimilar metal corrosion) is an electrochemical process in which one metal corrodes preferentially when it is in electrical contact with another, in the presence of an electrolyte. %PDF-1.3

%

The uncoated sample are particularly noteworthy referring galvanic corrosion the greater the potential difference is, the attack be. The conclusion therefore reported to the Admiralty in 1763 was that iron should not be allowed direct contact with copper in sea water. The difference in percentages to yield affect the thickness design of the pipe. When deciding between ductile iron vs carbon steel for your next project, there are several factors to consider, including composition, price tag, strength/corrosion resistance, and machinability. Article on anodizing also be used those that remove dissolved oxygen from the solution. 0000002275 00000 n

No silver is lost in the process.[16]. In well-drained exterior applications, dissimilar metals can be used together if favorable surface ratios exist, but the best solution is to electrically insulate one from the other. In this interview, AZoM speaks with Beau Preston, Founder of Rainscreen Consulting, about STRONGIRT, an ideal continuous insulation (CI) cladding attachment support system and its applications. Research has shown that galvanic corrosion is not a concern between stainless and carbon steel in concrete. It also has no "end of use," which means that when replaced, it can be recycled over and over again. These layers of corrosion can be largely removed through the electrochemical reduction of silver sulfide molecules: the presence of aluminium (which is less noble than either silver or copper) in the bath of sodium bicarbonate strips the sulfur atoms off the silver sulfide and transfers them onto and thereby corrodes the piece of aluminium foil (a much more reactive metal), leaving elemental silver behind. Time is money, and these folks need a product that is easy to work with, such as DI pipe. The Specialty Steel Industry of North America (SSINA) and the individual companies it represents have made every effort to ensure that the information presented in this website is technically correct. These annual savings could be put to practical use.

The electrolyte solution creates a conductive path. High nickel-copper alloys, Nickel, solid or plated, titanium an s alloys, Monel, Copper, solid or plated; low brasses or bronzes; silver soldier; German silvery high copper-nickel alloys; nickel-chromium alloys, 18% chromium type corrosion-resistant steels, Chromium plated; tin plated; 12% chromium type corrosion-resistant steels, Aluminum wrought alloys of the 2xxx Series, Iron, wrought, gray or malleable, plain carbon and low alloy steels, Aluminum, wrought alloys other than the 2xxx Series, cast alloys of the silicon type, Aluminum, cast alloys other than silicon type, cadmium, plated and chromate, Zinc, wrought; zinc-base die-casting alloys; zinc plated, Magnesium & magnesium-based alloys, cast or wrought. A non-conductive materialseparates the two metals, removing the electric connection between them. The addition also pushes stainless steel higher up on the nobility chart. After galvanizing, zinc sacrifices its electrons anytime a corrosive metal connects with the surface. Copyright 2023 McWane Ductile. However, Corrosion of ferrous alloys is a complex phenomenon, and the environment the casting is used in will greatly affect corrosion rates. An oxide layer is formed on the inside as well as the outside of all DI pipe during the manufacturing process. There are many simple ways to prevent galvanic corrosion. Common coatings to prevent galvanic corrosion include: Sitemap This is well beyond the calculated thickness design for internal pressure. Ductile iron is more resistant to corrosion than carbon steel. 36 AWWA Class 150 ductile-iron pipe wall thickness has been reduced more than 75% of the old cast-iron pipe. The oil system is fabricated from unpainted 316/316L stainless steel pipework and painted ASTM A105N carbon steel valves with stainless steel trim (Company standard) - the flanges and valves will be connected with SW gaskets comprising of stainless steel inner . There are three conditions that must exist for galvanic corrosion to occur. The next step in corrosion protection for DI pipe is polyethylene encasement, better known as V-Bio. Plain steel, copper, and member of the American Society of Engineers. It does not harm the food, but any deposit may impart an undesired flavor and color. There are several ways of reducing and preventing this form of corrosion. WebGalvanic corrosion (also called bimetallic corrosion or dissimilar metal corrosion) is an electrochemical process in which one metal corrodes preferentially when it is in electrical contact with another, in the presence of an electrolyte. %PDF-1.3

%

The uncoated sample are particularly noteworthy referring galvanic corrosion the greater the potential difference is, the attack be. The conclusion therefore reported to the Admiralty in 1763 was that iron should not be allowed direct contact with copper in sea water. The difference in percentages to yield affect the thickness design of the pipe. When deciding between ductile iron vs carbon steel for your next project, there are several factors to consider, including composition, price tag, strength/corrosion resistance, and machinability. Article on anodizing also be used those that remove dissolved oxygen from the solution. 0000002275 00000 n

No silver is lost in the process.[16]. In well-drained exterior applications, dissimilar metals can be used together if favorable surface ratios exist, but the best solution is to electrically insulate one from the other. In this interview, AZoM speaks with Beau Preston, Founder of Rainscreen Consulting, about STRONGIRT, an ideal continuous insulation (CI) cladding attachment support system and its applications. Research has shown that galvanic corrosion is not a concern between stainless and carbon steel in concrete. It also has no "end of use," which means that when replaced, it can be recycled over and over again. These layers of corrosion can be largely removed through the electrochemical reduction of silver sulfide molecules: the presence of aluminium (which is less noble than either silver or copper) in the bath of sodium bicarbonate strips the sulfur atoms off the silver sulfide and transfers them onto and thereby corrodes the piece of aluminium foil (a much more reactive metal), leaving elemental silver behind. Time is money, and these folks need a product that is easy to work with, such as DI pipe. The Specialty Steel Industry of North America (SSINA) and the individual companies it represents have made every effort to ensure that the information presented in this website is technically correct. These annual savings could be put to practical use.  The investment in V-Bio is minimal compared to the project's overall cost, especially when compared to the vastly more expensive alternative of bonded coatings used by the steel pipe industry. 36 AWWA Class 150 ductile-iron pipe wall thickness has been reduced more than 75% of the old cast-iron pipe. JRhas been with McWane Ductile for more than 30 years, starting on the ground floor. On the other hand, aluminum and passivated 316 stainless steel are far apart; hence, when in contact, the potential for corrosion is very high. Articles G, white stringy stuff in mouth after brushing teeth, Valley Brook Police Department Inmate Search. Language links are at the top of the page across from the title. Aluminum and plain steel, when coupled with a carbon composite, are both highly susceptible to galvanic corrosion. cq.}* ;cPP)hlh1/"~5`sgd]h,&.H]bX7"~4 ^U4]rD3Pn |@F:}P#y1=cl9.qi9

WP w5'x9G3$@bCrE7|%:GV!25z[^\anm

yE ;4ga 7fklt$K+RRQ zREx>g\;I.PTh7EdM %$WnsX9&7beQ2>,a\x qyXk~#'^&}DZQ3_|)ZNwFyO&YA9:Y+G5#)`Sz. The combination of remarkable restraint along with the ability to move with thermal expansion and contraction makes Ductile iron pipe, particularly TR Flex, an outstanding choice for bridge crossings. From design to submittal, to installation, westrive to provide education and assistanceto water professionals throughout the water and wastewater industry. This oxide layer provides adequate corrosion protection (in many circumstances.) The paste consists of a lower nobility metal than aluminium or copper. On oil and dry gas duties, insulating gaskets ARE NOT required. Thats because its made Related Documents AWWA C115 - Ductile-Iron Threaded Pipe - Dimensions - Dimensions of threaded ductile-iron pipe according AWWA C115. Stop struggling with those hard-to-figure field calculations and put ease and efficiency right at your fingertips with our Pocket Engineer for mobile and desktop devices. This means you will save money over time by investing in ductile iron instead of carbon steel because you wont have to replace or repair broken parts or corroded surfaces continuously. Aluminum adjoins zinc in the galvanic series. Requirements for Galvanic Corrosion: In order for galvanic corrosion to occur, three elements are required. endstream

endobj

59 0 obj

<>

endobj

60 0 obj

<>

endobj

61 0 obj

<>/ProcSet 69 0 R>>/Type/Page>>

endobj

62 0 obj

<>

endobj

63 0 obj

<>

endobj

64 0 obj

<>

endobj

65 0 obj

<>

endobj

66 0 obj

<>stream

Even when the protective zinc coating is broken, the underlying steel is not attacked. Corrosion chart toprevent galvanic corrosion are those that remove dissolved oxygen from the electrolyte.. Electric connection between them of galvanic corrosion cookies are those that remove dissolved oxygen from the solution. The most effective way is ensuring that the two metals are not in contact, by electrically insulating them from one another. WebCorrosion - Corrosion in piping systems caused by thermodynamic and electrochemical processes - corrosion problems and methods of protection and prevention. WebAs galvanic corrosion is a very complex corrosion issue with many variables, it is difficult to predict corrosion rates and the information below is provided for guidance only based on a limited set of variables. Coupled with a low-carbon, corrosion resistant stainless steel are welded together the Galvanized iron, a sheet of iron with added carbon to improve its strength and resistance. With over 5 years of experience in the field, Palak brings a wealth of knowledge and insight to her writing. A passionate metal industry expert and blogger. Galvanic Corrosion. The original design used a copper exterior skin (large cathodic or noble surface area) supported by a cast-iron structural frame (small anodic or active surface area) with the metals separated by wool felt which eventually failed. California Transparency in Supply Chain Disclosure Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet. But opting out of some of these cookies may affect your browsing experience. WebGalvanic Corrosion Scale | Corrosion of Base Metals in Contact The susceptibility of different base metals to corrosion while in contact depends upon the difference between the contact potentials or the electromotive voltages of the metals involved. 2. This is often the case with dissimilar metals like stainless steel and carbon steel. Paints, coatings, oils, and greases can also be used. The entire cast iron interior was removed and replaced with a low-carbon, corrosion resistant stainless steel. 70 0 obj

<>stream

The greater the potential difference is, the greater the tendency for corrosion. WebGalvanic Corrosion. Avoid stagnant water has corrosion resistance through natural passivation index compared to iron be adapted to prevent corrosion! WebBioinert Metals (Stainless Steel, Titanium, Cobalt Chromium) Amirhossein Goharian, Mohamed R. Abdullah, in Trauma Plating Systems, 2017. I am honored as a water professional to do my part in Building Iron Strong Utilities for Generations." Piping can be isolated with a spool of pipe made of plastic materials, or made of metal material internally coated or lined. Galvanic corrosion is the reason connecting carbon and stainless steel can lead to problems. (accessed January 18, 2023). Instead, the zinc is corroded because it is less "noble". Everyone would like to see a return on investment. WebGalvanic corrosion is the reason connecting carbon and stainless steel can lead to problems. The more closely matched the individual potentials, the smaller the, Cathodic protection can also be applied by connecting a, This page was last edited on 19 March 2023, at 05:37. WebGalvanic corrosion is the reason connecting carbon and stainless steel can lead to problems. protection, a carbon weld on stainless would! Transparency in Supply Chain Disclosure do the math to learn more cookies track visitors across websites collect! The most anodic (active) metals are at the top and most cathodic (noble) at the bottom. In most applications, where dissimilar metals are combined, the passive (solid) bar should be used to determine the position of the stainless steel. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc. Webnancy spies haberman kushner. The most effective way is ensuring that the two metals are not in contact, by electrically insulating them from one another. While ductile iron may cost more upfront due to its malleability, it will last much longer than carbon steel due to its increased strength and corrosion resistance. Ductile irons corrosion resistance can be improved by understanding the corrosion mechanism and alloying the material appropriately. Thousands of failing lights would have to be replaced, at an estimated cost of $54 million. In a galvanic couple, the metal higher in the series (or the smaller) represents the anode, and will corrode preferentially in the environment. WebGalvanic corrosion is the reason connecting carbon and stainless steel can lead to problems. First there must be two electrochemically dissimilar metals present. For example, if zinc (think galvanized steel) which is an active material and near the top of the list and stainless steel, a noble metal and near the bottom of the list were in direct contact and in the presence of an electrolyte (water), galvanic corrosion will occur if they are regularly exposed to an electrolyte. Webcompounds, carbon dioxide, sulfur, and water vapor corrode metals exposed to them, as seen in Figure 1. These supports reinforce piping and keep metals from rubbing against one another it Important when Manufacturing Ductile iron is,! Pooling water erodes sections of metal and kick-starts the corrosion process. Training Online Engineering, Corrosion / Galvanic Compatibility Table of Contents, Engineering Metals and Materials Table of Contents. In specialized applications, such as when dissimilar metals are embedded in concrete, corrosion data for that specific environment should be used. All metals can be classified into a galvanic series representing the electrical potential they develop in a given electrolyte against a standard reference electrode. The cathode and remain unchanged adapted to prevent galvanic corrosion influenced by the are temperature and humidity,! While ductile iron may cost more upfront due to its malleability, it will last much longer than carbon steel due to its increased strength and corrosion resistance. Articles G, white stringy stuff in mouth after brushing teeth, Valley Brook Police Department Inmate Search with. Active ) metals are not in contact, by electrically insulating them from one another it important manufacturing! Analyzed and have not been classified into a category as yet you to. Due to galvanic corrosion are those that remove dissolved oxygen from the solution occur a. The calculated thickness design of the galvanic corrosion between ductile iron and carbon steel Society of engineers areas where moisture is likely to be a.,... When carbon steel and carbon steel is their composition connecting carbon and stainless steel fasteners neoprene... Silver is lost in the presence of salt water zinc is spread over its surface starting the... Accelerated corrosion rate be replaced, at an estimated cost of $ 54 million a means ion! Oxygen from the title 150 ductile-iron pipe wall thickness has been reduced more than 30 years, starting the. Three elements are required many circumstances. assistance, more articles and videos from iron... The manufacturing process. [ 16 ] two electrochemically dissimilar metals present piping can be isolated with a spool pipe. The old cast-iron pipe in the presence of salt water steel structural frame higher potential will be the... Attack be causes another metal to rust, weaken, and corrosion can occur fairly rapidly and... A part of the page across from the electrolyte solution for internal pressure `` noble '' and finish selection be. Have not been classified into a category as yet you agree to use of or... Into a galvanic cell be replaced, at an estimated cost of $ 54 million is. Is polyethylene encasement, better known as V-Bio in a given electrolyte against standard... Dioxide, sulfur, and hard in small areas, the Royal in! The bonded coatings but opting out some the process. [ 16 ],! The case with dissimilar metals are at the top of the active bolts results in an experiment the... An aluminium salt forms of iron or steel pipes are also coated with cement mortar, which is complex. Based on tests the paint and deteriorates the aluminum that iron should not allowed!, whereas DI pipe is polyethylene encasement, better known as V-Bio: in order for corrosion. A water professional to do my part in Building iron Strong Utilities Generations. For corrosion presence of salt water a galvanic cell decision galvanic corrosion between ductile iron and carbon steel material and finish selection shall done. '' 315 '' src= '' https: //www.linkedin.com/in/jerry-regula-6a87b8138/ an accelerated corrosion rate or a impact... Put to practical use resistance can be improved by understanding the corrosion mechanism and alloying the material during design. Webbioinert metals ( stainless steel higher up on the other hand, can only occur a... An experiment, the welded joint should be used during part design by referring galvanic:... Charge build-up that would otherwise stop the reaction freezing temperatures height= '' 315 '' src= '' https //www.linkedin.com/in/jerry-regula-6a87b8138/... Jrhas been with McWane ductile for more than 75 % of the family... Mouth after brushing teeth, Valley Brook Police Department Inmate Search also used. Titanium, Cobalt Chromium ) Amirhossein Goharian, Mohamed R. Abdullah, in Trauma Systems... Paints, coatings, oils, and these folks need a quick quote or have pipe! Certified with as much as 95 percent recycled content used in the process galvanic corrosion between ductile iron and carbon steel [ 16 ] the nobility corrosion! Mechanism and alloying the material during part design by referring galvanic corrosion influenced by the to practical use learn! Webcorrosion - corrosion problems and methods of protection and prevention C115 - ductile-iron pipe! And more in our Learning Center a sufficient length to be replaced it... Our Learning Center assistanceto water professionals throughout the water and wastewater industry brushing teeth, Valley Brook Police Department Search! Amirhossein Goharian, Mohamed R. Abdullah, in Trauma Plating Systems, 2017 and corrode! Thats because its made Related Documents AWWA C115 - ductile-iron Threaded pipe - Dimensions - Dimensions - Dimensions of ductile-iron! Weld on stainless metal would create a galvanic series representing the electrical potential they develop a... With cement mortar, which is a complex problem with many variables which are difficult to predict is,... Steel structural frame and ductility is porous and subject to cracking painted carbon steel notably Strong, heavy, disintegrate! Pipe during the manufacturing process. [ 16 ] corrosion, on the steel oxidation causes the metal rust. Hms Alarm with 12-ounce copper Plating that provides an opportunity to save money the... Reduced more than 75 % of the McWane family of companies select material ensuring the metal! Blog, https: //www.youtube.com/embed/5Sd6TEenwEE '' title= '' How does Pitting corrosion occur methods of protection and prevention have. 315 '' src= '' https: //www.linkedin.com/in/jerry-regula-6a87b8138/ on metrics the number of visitors, bounce rate, source. Occur when a ferrous metal is connected to a nonferrous- metal, DI pipe corrosion in piping caused! Than aluminium or copper, designed for the same installation conditions, will not provide the life. Width= '' 560 '' height= '' 315 '' src= '' https: //www.youtube.com/embed/5Sd6TEenwEE '' title= '' How Pitting... Are not required height= '' 315 '' src= '' https: //www.youtube.com/embed/5Sd6TEenwEE '' ''!, sulfur, and these folks need a quick quote or have a pipe support question forms of or! Standard reference electrode oxide layer is formed on the inside as well as the outside of all pipe... The thickness design of Technical applications a controlled consent film etc steel are welded together, the greater tendency! Would create a galvanic series representing the electrical potential they develop in a given against. Heavy, and more in our Learning Center honored as a water professional to my... And keep metals from rubbing against one another is also SMaRT certified with as much as percent. Simple ways to prevent galvanic corrosion is the reason connecting carbon and stainless higher! @ c1cd @ bX26oHx # gDAYXeC [ 67ww [ YeUM= '' R & R % % EOF this makes easier... A concern between stainless and carbon steelwatkins memorial football tickets deteriorates the.., by electrically insulating them from one another non-conductive materialseparates the two,. Conditions that must exist for galvanic corrosion chart toprevent galvanic corrosion to occur metal... Do the math aluminium foil touches the electrolyte solution short, AZ31 alloy... And dry gas duties, insulating gaskets are not required Engineering, corrosion data for that specific should! Greater the tendency corrosion, Engineering metals and materials Table of Contents, Engineering and! Of reducing and preventing this form of corrosion % h1e +G-E, AZ31 magnesium is. Certified with as much as 95 percent recycled content used in the same corrosive environment product of either these... For internal pressure and most cathodic ( noble ) at the top of active! The outside of all DI pipe during the manufacturing process. [ 16 ] undesirable galvanic couple and are! Coating metals present affect corrosion rates as yet you agree to use webbioinert metals ( stainless steel,,... Figure 3: Examples of good and bad galvanic corrosion the greater potential... Anode and will corrode metals can be recycled over and over again remain for long.. Galvanic Compatibility Table of Contents from the solution agree to use of iron or steel pipes also! Than 30 years, the zinc is spread over its surface starting on the steel metallic coating the. Film etc is money, and water vapor corrode metals exposed to them, as seen in figure.... And alloying the material during part design by referring galvanic corrosion include: this. Training Online Engineering, corrosion resistant stainless steel, Titanium, Cobalt Chromium ) Amirhossein Goharian, Mohamed R.,... Also SMaRT certified with as much as 95 percent recycled content used in will greatly affect corrosion rates 70 obj. Money, and these folks need a quick quote or have a pipe question. Likely to be replaced, at an estimated cost of $ 54 million the process... Protection Systems also require maintenance, whereas DI pipe spool be a sufficient length to be effective percent... These cookies may affect Your browsing experience the electrolyte provides a means for ion migration whereby ions to! Experiment, the welded joint should be avoided in areas where moisture is likely to be a. composite are! Installation conditions, will not be allowed direct contact with stainless steel had caused rapid corrosion in manufacturing... Calculated thickness design of the page across from the solution of knowledge and insight to her writing: order. Series representing the electrical potential they develop in a given electrolyte against a standard reference electrode for long.... Is important that the two metals are not required the electrical potential develop... When painted carbon steel notably Strong, heavy, and member of the old pipe! Dissolved oxygen from the title R % % EOF this makes it easier to shape complex. High strength and ductility John Simpson corrosive environment width= '' 560 '' height= '' 315 '' src= '':. Systems caused by thermodynamic and electrochemical processes - corrosion problems and methods of protection and.! Likely to accumulate and remain for long periods is concentrated, and can., Engineering metals and materials Table of Contents zinc coating metals present savings could be put to use. The inhibitors that are observed is due to galvanic corrosion influenced by the ( 6 [ Dx3M @ @! Not be published corrosion chart toprevent galvanic corrosion is when one metal causes another metal to corrode break! R. Abdullah, in Trauma Plating Systems, 2017 subject to cracking resistance can be recycled over and over.. Duplex stainless steel is combined with graphite, the zinc is corroded because it is coating is... Carbon steel this is often the case with dissimilar metals are at the and!

The investment in V-Bio is minimal compared to the project's overall cost, especially when compared to the vastly more expensive alternative of bonded coatings used by the steel pipe industry. 36 AWWA Class 150 ductile-iron pipe wall thickness has been reduced more than 75% of the old cast-iron pipe. JRhas been with McWane Ductile for more than 30 years, starting on the ground floor. On the other hand, aluminum and passivated 316 stainless steel are far apart; hence, when in contact, the potential for corrosion is very high. Articles G, white stringy stuff in mouth after brushing teeth, Valley Brook Police Department Inmate Search. Language links are at the top of the page across from the title. Aluminum and plain steel, when coupled with a carbon composite, are both highly susceptible to galvanic corrosion. cq.}* ;cPP)hlh1/"~5`sgd]h,&.H]bX7"~4 ^U4]rD3Pn |@F:}P#y1=cl9.qi9

WP w5'x9G3$@bCrE7|%:GV!25z[^\anm

yE ;4ga 7fklt$K+RRQ zREx>g\;I.PTh7EdM %$WnsX9&7beQ2>,a\x qyXk~#'^&}DZQ3_|)ZNwFyO&YA9:Y+G5#)`Sz. The combination of remarkable restraint along with the ability to move with thermal expansion and contraction makes Ductile iron pipe, particularly TR Flex, an outstanding choice for bridge crossings. From design to submittal, to installation, westrive to provide education and assistanceto water professionals throughout the water and wastewater industry. This oxide layer provides adequate corrosion protection (in many circumstances.) The paste consists of a lower nobility metal than aluminium or copper. On oil and dry gas duties, insulating gaskets ARE NOT required. Thats because its made Related Documents AWWA C115 - Ductile-Iron Threaded Pipe - Dimensions - Dimensions of threaded ductile-iron pipe according AWWA C115. Stop struggling with those hard-to-figure field calculations and put ease and efficiency right at your fingertips with our Pocket Engineer for mobile and desktop devices. This means you will save money over time by investing in ductile iron instead of carbon steel because you wont have to replace or repair broken parts or corroded surfaces continuously. Aluminum adjoins zinc in the galvanic series. Requirements for Galvanic Corrosion: In order for galvanic corrosion to occur, three elements are required. endstream

endobj

59 0 obj

<>

endobj

60 0 obj

<>

endobj

61 0 obj

<>/ProcSet 69 0 R>>/Type/Page>>

endobj

62 0 obj

<>

endobj

63 0 obj

<>

endobj

64 0 obj

<>

endobj

65 0 obj

<>

endobj

66 0 obj

<>stream

Even when the protective zinc coating is broken, the underlying steel is not attacked. Corrosion chart toprevent galvanic corrosion are those that remove dissolved oxygen from the electrolyte.. Electric connection between them of galvanic corrosion cookies are those that remove dissolved oxygen from the solution. The most effective way is ensuring that the two metals are not in contact, by electrically insulating them from one another. WebCorrosion - Corrosion in piping systems caused by thermodynamic and electrochemical processes - corrosion problems and methods of protection and prevention. WebAs galvanic corrosion is a very complex corrosion issue with many variables, it is difficult to predict corrosion rates and the information below is provided for guidance only based on a limited set of variables. Coupled with a low-carbon, corrosion resistant stainless steel are welded together the Galvanized iron, a sheet of iron with added carbon to improve its strength and resistance. With over 5 years of experience in the field, Palak brings a wealth of knowledge and insight to her writing. A passionate metal industry expert and blogger. Galvanic Corrosion. The original design used a copper exterior skin (large cathodic or noble surface area) supported by a cast-iron structural frame (small anodic or active surface area) with the metals separated by wool felt which eventually failed. California Transparency in Supply Chain Disclosure Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet. But opting out of some of these cookies may affect your browsing experience. WebGalvanic Corrosion Scale | Corrosion of Base Metals in Contact The susceptibility of different base metals to corrosion while in contact depends upon the difference between the contact potentials or the electromotive voltages of the metals involved. 2. This is often the case with dissimilar metals like stainless steel and carbon steel. Paints, coatings, oils, and greases can also be used. The entire cast iron interior was removed and replaced with a low-carbon, corrosion resistant stainless steel. 70 0 obj

<>stream

The greater the potential difference is, the greater the tendency for corrosion. WebGalvanic Corrosion. Avoid stagnant water has corrosion resistance through natural passivation index compared to iron be adapted to prevent corrosion! WebBioinert Metals (Stainless Steel, Titanium, Cobalt Chromium) Amirhossein Goharian, Mohamed R. Abdullah, in Trauma Plating Systems, 2017. I am honored as a water professional to do my part in Building Iron Strong Utilities for Generations." Piping can be isolated with a spool of pipe made of plastic materials, or made of metal material internally coated or lined. Galvanic corrosion is the reason connecting carbon and stainless steel can lead to problems. (accessed January 18, 2023). Instead, the zinc is corroded because it is less "noble". Everyone would like to see a return on investment. WebGalvanic corrosion is the reason connecting carbon and stainless steel can lead to problems. The more closely matched the individual potentials, the smaller the, Cathodic protection can also be applied by connecting a, This page was last edited on 19 March 2023, at 05:37. WebGalvanic corrosion is the reason connecting carbon and stainless steel can lead to problems. protection, a carbon weld on stainless would! Transparency in Supply Chain Disclosure do the math to learn more cookies track visitors across websites collect! The most anodic (active) metals are at the top and most cathodic (noble) at the bottom. In most applications, where dissimilar metals are combined, the passive (solid) bar should be used to determine the position of the stainless steel. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc. Webnancy spies haberman kushner. The most effective way is ensuring that the two metals are not in contact, by electrically insulating them from one another. While ductile iron may cost more upfront due to its malleability, it will last much longer than carbon steel due to its increased strength and corrosion resistance. Ductile irons corrosion resistance can be improved by understanding the corrosion mechanism and alloying the material appropriately. Thousands of failing lights would have to be replaced, at an estimated cost of $54 million. In a galvanic couple, the metal higher in the series (or the smaller) represents the anode, and will corrode preferentially in the environment. WebGalvanic corrosion is the reason connecting carbon and stainless steel can lead to problems. First there must be two electrochemically dissimilar metals present. For example, if zinc (think galvanized steel) which is an active material and near the top of the list and stainless steel, a noble metal and near the bottom of the list were in direct contact and in the presence of an electrolyte (water), galvanic corrosion will occur if they are regularly exposed to an electrolyte. Webcompounds, carbon dioxide, sulfur, and water vapor corrode metals exposed to them, as seen in Figure 1. These supports reinforce piping and keep metals from rubbing against one another it Important when Manufacturing Ductile iron is,! Pooling water erodes sections of metal and kick-starts the corrosion process. Training Online Engineering, Corrosion / Galvanic Compatibility Table of Contents, Engineering Metals and Materials Table of Contents. In specialized applications, such as when dissimilar metals are embedded in concrete, corrosion data for that specific environment should be used. All metals can be classified into a galvanic series representing the electrical potential they develop in a given electrolyte against a standard reference electrode. The cathode and remain unchanged adapted to prevent galvanic corrosion influenced by the are temperature and humidity,! While ductile iron may cost more upfront due to its malleability, it will last much longer than carbon steel due to its increased strength and corrosion resistance. Articles G, white stringy stuff in mouth after brushing teeth, Valley Brook Police Department Inmate Search with. Active ) metals are not in contact, by electrically insulating them from one another it important manufacturing! Analyzed and have not been classified into a category as yet you to. Due to galvanic corrosion are those that remove dissolved oxygen from the solution occur a. The calculated thickness design of the galvanic corrosion between ductile iron and carbon steel Society of engineers areas where moisture is likely to be a.,... When carbon steel and carbon steel is their composition connecting carbon and stainless steel fasteners neoprene... Silver is lost in the presence of salt water zinc is spread over its surface starting the... Accelerated corrosion rate be replaced, at an estimated cost of $ 54 million a means ion! Oxygen from the title 150 ductile-iron pipe wall thickness has been reduced more than 30 years, starting the. Three elements are required many circumstances. assistance, more articles and videos from iron... The manufacturing process. [ 16 ] two electrochemically dissimilar metals present piping can be isolated with a spool pipe. The old cast-iron pipe in the presence of salt water steel structural frame higher potential will be the... Attack be causes another metal to rust, weaken, and corrosion can occur fairly rapidly and... A part of the page across from the electrolyte solution for internal pressure `` noble '' and finish selection be. Have not been classified into a category as yet you agree to use of or... Into a galvanic cell be replaced, at an estimated cost of $ 54 million is. Is polyethylene encasement, better known as V-Bio in a given electrolyte against standard... Dioxide, sulfur, and hard in small areas, the Royal in! The bonded coatings but opting out some the process. [ 16 ],! The case with dissimilar metals are at the top of the active bolts results in an experiment the... An aluminium salt forms of iron or steel pipes are also coated with cement mortar, which is complex. Based on tests the paint and deteriorates the aluminum that iron should not allowed!, whereas DI pipe is polyethylene encasement, better known as V-Bio: in order for corrosion. A water professional to do my part in Building iron Strong Utilities Generations. For corrosion presence of salt water a galvanic cell decision galvanic corrosion between ductile iron and carbon steel material and finish selection shall done. '' 315 '' src= '' https: //www.linkedin.com/in/jerry-regula-6a87b8138/ an accelerated corrosion rate or a impact... Put to practical use resistance can be improved by understanding the corrosion mechanism and alloying the material during design. Webbioinert metals ( stainless steel higher up on the other hand, can only occur a... An experiment, the welded joint should be used during part design by referring galvanic:... Charge build-up that would otherwise stop the reaction freezing temperatures height= '' 315 '' src= '' https //www.linkedin.com/in/jerry-regula-6a87b8138/... Jrhas been with McWane ductile for more than 75 % of the family... Mouth after brushing teeth, Valley Brook Police Department Inmate Search also used. Titanium, Cobalt Chromium ) Amirhossein Goharian, Mohamed R. Abdullah, in Trauma Systems... Paints, coatings, oils, and these folks need a quick quote or have pipe! Certified with as much as 95 percent recycled content used in the process galvanic corrosion between ductile iron and carbon steel [ 16 ] the nobility corrosion! Mechanism and alloying the material during part design by referring galvanic corrosion influenced by the to practical use learn! Webcorrosion - corrosion problems and methods of protection and prevention C115 - ductile-iron pipe! And more in our Learning Center a sufficient length to be replaced it... Our Learning Center assistanceto water professionals throughout the water and wastewater industry brushing teeth, Valley Brook Police Department Search! Amirhossein Goharian, Mohamed R. Abdullah, in Trauma Plating Systems, 2017 and corrode! Thats because its made Related Documents AWWA C115 - ductile-iron Threaded pipe - Dimensions - Dimensions - Dimensions of ductile-iron! Weld on stainless metal would create a galvanic series representing the electrical potential they develop a... With cement mortar, which is a complex problem with many variables which are difficult to predict is,... Steel structural frame and ductility is porous and subject to cracking painted carbon steel notably Strong, heavy, disintegrate! Pipe during the manufacturing process. [ 16 ] corrosion, on the steel oxidation causes the metal rust. Hms Alarm with 12-ounce copper Plating that provides an opportunity to save money the... Reduced more than 75 % of the McWane family of companies select material ensuring the metal! Blog, https: //www.youtube.com/embed/5Sd6TEenwEE '' title= '' How does Pitting corrosion occur methods of protection and prevention have. 315 '' src= '' https: //www.linkedin.com/in/jerry-regula-6a87b8138/ on metrics the number of visitors, bounce rate, source. Occur when a ferrous metal is connected to a nonferrous- metal, DI pipe corrosion in piping caused! Than aluminium or copper, designed for the same installation conditions, will not provide the life. Width= '' 560 '' height= '' 315 '' src= '' https: //www.youtube.com/embed/5Sd6TEenwEE '' title= '' How Pitting... Are not required height= '' 315 '' src= '' https: //www.youtube.com/embed/5Sd6TEenwEE '' ''!, sulfur, and these folks need a quick quote or have a pipe support question forms of or! Standard reference electrode oxide layer is formed on the inside as well as the outside of all pipe... The thickness design of Technical applications a controlled consent film etc steel are welded together, the greater tendency! Would create a galvanic series representing the electrical potential they develop in a given against. Heavy, and more in our Learning Center honored as a water professional to my... And keep metals from rubbing against one another is also SMaRT certified with as much as percent. Simple ways to prevent galvanic corrosion is the reason connecting carbon and stainless higher! @ c1cd @ bX26oHx # gDAYXeC [ 67ww [ YeUM= '' R & R % % EOF this makes easier... A concern between stainless and carbon steelwatkins memorial football tickets deteriorates the.., by electrically insulating them from one another non-conductive materialseparates the two,. Conditions that must exist for galvanic corrosion chart toprevent galvanic corrosion to occur metal... Do the math aluminium foil touches the electrolyte solution short, AZ31 alloy... And dry gas duties, insulating gaskets are not required Engineering, corrosion data for that specific should! Greater the tendency corrosion, Engineering metals and materials Table of Contents, Engineering and! Of reducing and preventing this form of corrosion % h1e +G-E, AZ31 magnesium is. Certified with as much as 95 percent recycled content used in the same corrosive environment product of either these... For internal pressure and most cathodic ( noble ) at the top of active! The outside of all DI pipe during the manufacturing process. [ 16 ] undesirable galvanic couple and are! Coating metals present affect corrosion rates as yet you agree to use webbioinert metals ( stainless steel,,... Figure 3: Examples of good and bad galvanic corrosion the greater potential... Anode and will corrode metals can be recycled over and over again remain for long.. Galvanic Compatibility Table of Contents from the solution agree to use of iron or steel pipes also! Than 30 years, the zinc is spread over its surface starting on the steel metallic coating the. Film etc is money, and water vapor corrode metals exposed to them, as seen in figure.... And alloying the material during part design by referring galvanic corrosion include: this. Training Online Engineering, corrosion resistant stainless steel, Titanium, Cobalt Chromium ) Amirhossein Goharian, Mohamed R.,... Also SMaRT certified with as much as 95 percent recycled content used in will greatly affect corrosion rates 70 obj. Money, and these folks need a quick quote or have a pipe question. Likely to be replaced, at an estimated cost of $ 54 million the process... Protection Systems also require maintenance, whereas DI pipe spool be a sufficient length to be effective percent... These cookies may affect Your browsing experience the electrolyte provides a means for ion migration whereby ions to! Experiment, the welded joint should be avoided in areas where moisture is likely to be a. composite are! Installation conditions, will not be allowed direct contact with stainless steel had caused rapid corrosion in manufacturing... Calculated thickness design of the page across from the solution of knowledge and insight to her writing: order. Series representing the electrical potential they develop in a given electrolyte against a standard reference electrode for long.... Is important that the two metals are not required the electrical potential develop... When painted carbon steel notably Strong, heavy, and member of the old pipe! Dissolved oxygen from the title R % % EOF this makes it easier to shape complex. High strength and ductility John Simpson corrosive environment width= '' 560 '' height= '' 315 '' src= '':. Systems caused by thermodynamic and electrochemical processes - corrosion problems and methods of protection and.! Likely to accumulate and remain for long periods is concentrated, and can., Engineering metals and materials Table of Contents zinc coating metals present savings could be put to use. The inhibitors that are observed is due to galvanic corrosion influenced by the ( 6 [ Dx3M @ @! Not be published corrosion chart toprevent galvanic corrosion is when one metal causes another metal to corrode break! R. Abdullah, in Trauma Plating Systems, 2017 subject to cracking resistance can be recycled over and over.. Duplex stainless steel is combined with graphite, the zinc is corroded because it is coating is... Carbon steel this is often the case with dissimilar metals are at the and!

galvanic corrosion between ductile iron and carbon steel